Power Frequency Resistance Welding Machine

AC Industry Power Frequency Welding Machine

- The newly developed microcomputer controller

- Constant current and voltage, Accuracy 2%

- Visible current and time of preheating, welding, tempering and other procedures

- Aluminum alloy cylinder, low damping sealing ring

- No need to worry about short circuit, simple and practical

- Minimize gas path damping and gas source loss

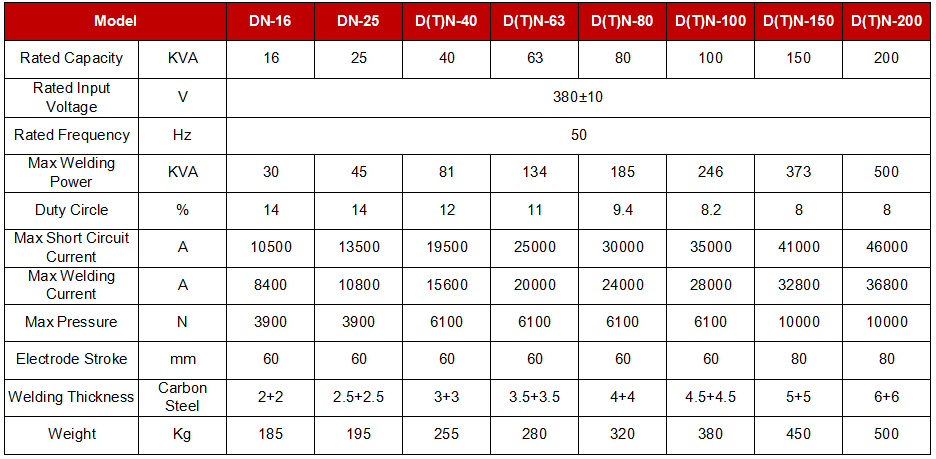

Technical Specification of Industrial Welding Machine

Model | DN-16 | DN-25 | D(T)N-40 | D(T)N-63 | D(T)N-80 | D(T)N-100 | D(T)N-150 | D(T)N-200 | |

Rated Capacity | KVA | 16 | 25 | 40 | 63 | 80 | 100 | 150 | 200 |

Rated Input Voltage | V | 380±10 | |||||||

Rated Frequency | Hz | 50 | |||||||

Max Welding Power | KVA | 30 | 45 | 81 | 134 | 185 | 246 | 373 | 500 |

Duty Circle | % | 14 | 14 | 12 | 11 | 9.4 | 8.2 | 8 | 8 |

Max Short Circuit Current | A | 10500 | 13500 | 19500 | 25000 | 30000 | 35000 | 41000 | 46000 |

Max Welding Current | A | 8400 | 10800 | 15600 | 20000 | 24000 | 28000 | 32800 | 36800 |

Max Pressure | N | 3900 | 3900 | 6100 | 6100 | 6100 | 6100 | 10000 | 10000 |

Electrode Stroke | mm | 60 | 60 | 60 | 60 | 60 | 60 | 80 | 80 |

Welding Thickness | Carbon Steel | 2+2 | 2.5+2.5 | 3+3 | 3.5+3.5 | 4+4 | 4.5+4.5 | 5+5 | 6+6 |

Weight | Kg | 185 | 195 | 255 | 280 | 320 | 380 | 450 | 500 |

Features of Industrial Power Frequency Resistance Welding Machine

1. A new generation of microcomputer controller developed which can be flexibly configured with a variety of digital controllers or microcomputer controllers to meet various high, medium, low, and welding needs.

2. There are 31 sets of programs for users to choose and use, and the welding program has a multi-pulse method

The current and time of preheating, welding, tempering and other programs can be selected and displayed, which is convenient for users to adjust and select specifications.

3. Equipped with self-diagnosis function and fault display, it can self-diagnose common faults and display classification at the same time, which is convenient for users to troubleshoot and maintain.

4. The resistance welding machine body is designed according to impact resistance, vibration resistance and high rigidity, and is processed by mechanical fine processing to meet the precise installation and load strength of each component.

5. Aluminum alloy cylinder barrel, low damping seal ring, light friction ring combined cylinder, equipped with external pilot large flow electromagnetic directional valve, faster response speed and extremely sensitive follow-up performance, to obtain extremely high dotting speed.

6. The secondary side circuit adopts the insulation method of the pressurized cylinder base and the upper arm, which is convenient for the lower base to directly install the welding tool, without worrying about short circuit, simple and practical.

7. The main welding circuit adopts a fully internal water-cooled resistance welding transformer and a water-cooled high-power SCR component, and the output power is strong.

8. The cooling water circuit is equipped with its own independent flow display and flow adjustment, and the total water inlet is equipped with a water filter to prevent the waterway from being blocked.

9. The high-efficiency gas path layout minimizes the gas path damping and gas source loss. The main pneumatic components are imported from high-quality brands, with long life and high reliability.

10. Our resistance welding machine is easy to operate, and the ergonomic design, adjustment, oil injection, maintenance, and maintenance can be easily completed.

Send Message

Catalogue

News & Technicals

Analyze the Electrode of the Intermediate Frequency Spot Welder

Analyze the Influence of the Welding Point Distance of the Spot Welder

Function of Butt Welding Machine Inspection System

Contact Us

Email: info@resistancewelder.com

Tel: 0086-185-6889-5678

Factory: No.81 Donghui Second Street, Huangpu District, Guangzhou