Invert Resistance Spot Welding Machine

DC Power, Medium Frequency Spot Welder

- High welding efficiency, Power factor >98%

- Low impact on grid, DC output current

- 0 Inductor Impedance

- IP55 Standard Electrical System

- 1000 Hz Working Frequency, Timing Accuracy 1 ms;

- Programmable welding current, time and weld pressure

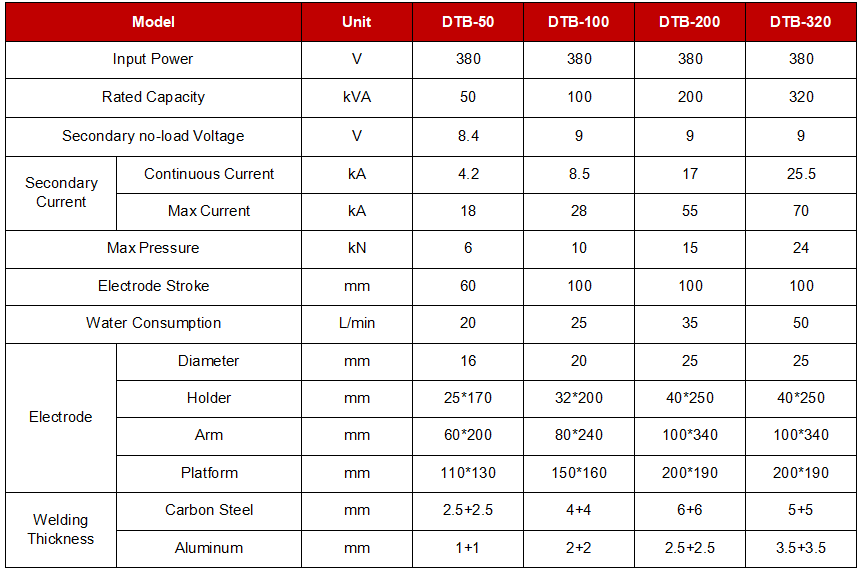

Technical Specification of Spot Welding Machine

| Model | Unit | DTB-50 | DTB-100 | DTB-200 | DTB-320 | |

| Input Power | V | 380 | 380 | 380 | 380 | |

| Rated Capacity | kVA | 50 | 100 | 200 | 320 | |

| Secondary no-load Voltage | V | 8.4 | 9 | 9 | 9 | |

| Secondary Current | Continuous Current | kA | 4.2 | 8.5 | 17 | 25.5 |

| Max Current | kA | 18 | 28 | 55 | 70 | |

| Max Pressure | kN | 6 | 10 | 15 | 24 | |

| Electrode Stroke | mm | 60 | 100 | 100 | 100 | |

| Water Consumption | L/min | 20 | 25 | 35 | 50 | |

| Electrode | Diameter | mm | 16 | 20 | 25 | 25 |

| Holder | mm | 25*170 | 32*200 | 40*250 | 40*250 | |

| Arm | mm | 60*200 | 80*240 | 100*340 | 100*340 | |

| Platform | mm | 110*130 | 150*160 | 200*190 | 200*190 | |

| Welding Thickness | Carbon Steel | mm | 2.5+2.5 | 4+4 | 6+6 | 5+5 |

| Aluminum | mm | 1+1 | 2+2 | 2.5+2.5 | 3.5+3.5 | |

Working Principle of Resistance Spot Welding Machine

Resistance spot welding machine uses the principle of resistance heating to weld. There are multiple types of electrode pressurization, such as lever type, electric cam type, pneumatic type, hydraulic type, and pneumatic and hydraulic combined type.

Spot welding is a resistance welding method in which the weldment is assembled into a lap joint and pressed between two cylindrical electrodes, and the base metal is melted by resistance heat to form a welding spot. Spot welding is mainly used for thin plate welding. Such as aircraft skins, fire chimneys of aviation engines, car cabin shells, etc.

The spot welding machines produced by our company mainly include

1. Intermediate frequency reverse spot welding machine:

This is the most advanced resistance welding technology at present. After being rectified by the transformer, the electrode outputs direct current, which can maximize the power factor, ensure the welding quality, and save energy by 30% ( Compared with single-phase communication). And this type of welding machine is welding some special materials, such as aluminum, aluminum alloy, galvanized sheet, etc., and the welding effect is excellent.

2. Three-phase secondary rectifier spot welding machine:

This type of welding machine is mainly used for spot projection welding. The main feature is that it can realize high-power welding, but has little impact on the power grid. Now it is also used for resistance welding of flash butt welding and seam welding.

3. AC frequency conversion welding system:

This type of welding machine is mainly used for seam welding. The main feature is to maintain three-phase balance, have a small impact on the power grid, and also have the advantages of energy saving and high power factor.

Features of Resistance Spot Welding Machine

1.The welding current is DC, and when there are inductive or magnetic materials in the secondary winding, it will not affect the welding.

2.Using the load balance of electrical equipment, the medium frequency inverter spot welding machine adopts three-phase power supply to be more adaptable to the fluctuation and voltage drop of the power grid.

3.More accurate and fast current control, compared with the industrial frequency system, it can analyze the parameters more accurately and accurately.

4. The set current can be reached faster, and the intermediate frequency can be 20 times faster than the traditional technology when adjusting the welding current.

5. The process is more reliable, and most of the metals that are used for welding resistance will be better if DC welding is used.

6.Reduce the cost of overwork, including saving each point of welding energy and shortening the welding cycle.

7. Save energy, especially suitable for welding thick workpieces and highly conductive metals, such as aluminum and all galvanized steel sheets.

Send Message

Catalogue

News & Technicals

Analyze the Electrode of the Intermediate Frequency Spot Welder

Analyze the Influence of the Welding Point Distance of the Spot Welder

Function of Butt Welding Machine Inspection System

Contact Us

Email: info@resistancewelder.com

Tel: 0086-185-6889-5678

Factory: No.81 Donghui Second Street, Huangpu District, Guangzhou